Colloidal silica is a highly versatile material with applications across a wide range of industries, from electronics and catalysts to coatings and ceramics. To produce colloidal silica, specific methods and processes are employed to create a stable dispersion of ultra-fine silica particles in a liquid medium. Understanding the production process of colloidal silica, including various techniques like the sol-gel method and the use of silica solutions, is crucial for optimizing its use in various applications.

Understanding Colloidal Silica Production

The production of colloidal silica involves transforming silicon compounds into tiny, amorphous silica particles suspended in a liquid. The primary goal is to produce stable colloidal solutions with specific properties, such as particle size, purity, and pH, tailored to meet the requirements of different applications.

Key Production Methods of Colloidal Silica

Sol-Gel Process:

The sol-gel process is a widely used method for producing high-purity silica sol. It involves the hydrolysis and condensation of silicon alkoxides, such as tetraethyl orthosilicate (TEOS), in an aqueous medium.

Step-by-Step Process:

Hydrolysis: Silicon alkoxide is mixed with water and an acid or base catalyst. This causes the silicon compound to hydrolyze, forming silanol groups (Si-OH).

Condensation: The silanol groups undergo condensation reactions, resulting in the formation of siloxane bonds (Si-O-Si) and the growth of silica particles.

Stabilization: Stabilizers or surfactants are added to maintain particle dispersion and prevent agglomeration. This creates a stable silica sol, or colloidal silica, with the desired particle size and distribution.

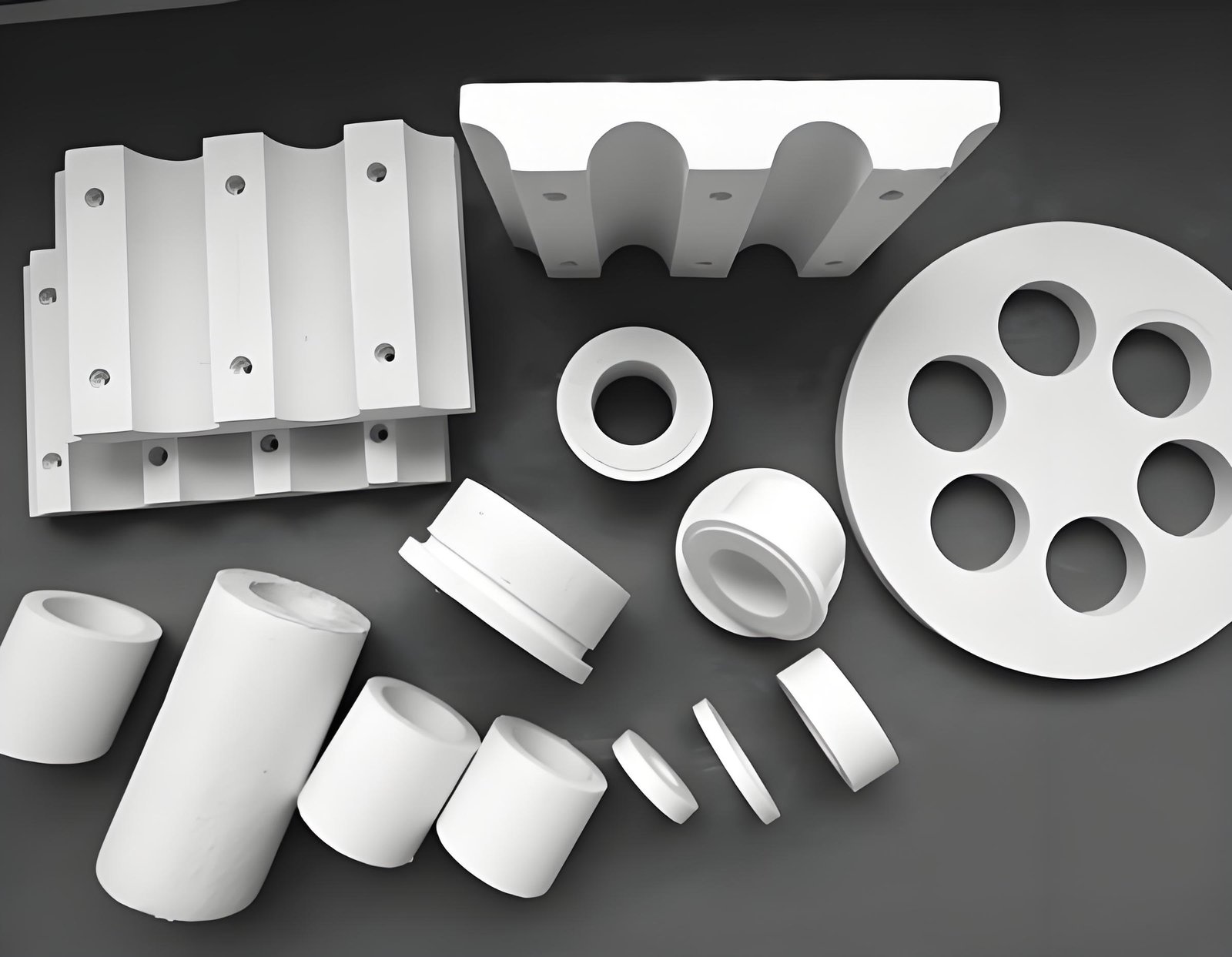

Applications: The sol-gel process produces high-purity silica sol used in precision coatings, electronics, and advanced ceramics due to its controlled particle size and purity.

Precipitation Method:

The precipitation method involves the controlled precipitation of silica from a silica solution of a soluble silicon compound, such as sodium silicate (water glass), through acidification.

Step-by-Step Process:

Acidification: Sodium silicate solution is gradually acidified using a mineral acid like sulfuric acid or hydrochloric acid, leading to the formation of silicic acid.

Polymerization: The silicic acid polymerizes to form silica particles, which aggregate to create a colloidal suspension.

Purification: The colloidal silica is filtered, washed, and stabilized to achieve the desired particle characteristics and remove any impurities.

Applications: This method is often used to produce colloidal silica for coatings, adhesives, and various industrial applications where moderate purity levels are acceptable.

Stöber Process:

The Stöber process is a specific sol-gel technique used to produce monodisperse (uniform size) nano silica sol particles.

Step-by-Step Process:

Hydrolysis: Silicon alkoxide (e.g., TEOS) is hydrolyzed in an alcohol solvent (e.g., ethanol) with water and a base catalyst (e.g., ammonia).

Condensation: The hydrolyzed product condenses to form uniform, spherical silica nanoparticles.

Stabilization: The colloidal silica is stabilized to prevent agglomeration, resulting in a high-purity nano silica sol.

Applications: This method produces high-purity, monodisperse nano-silica used in electronics polishing, biomedical applications, and high-performance coatings.

Alkaline Silicon Solution Method:

This method involves using an alkaline silicon solution to produce colloidal silica with specific properties.

Step-by-Step Process:

Silicon Source: A soluble silicon compound, such as sodium silicate, is dissolved in water to form an alkaline silicon solution.

Reaction: The solution is neutralized or mildly acidified to initiate silica precipitation, forming colloidal particles.

Stabilization: The colloidal silica is stabilized in an alkaline medium to prevent agglomeration and ensure uniform dispersion.

Applications: This process is used to produce colloidal silica for applications requiring alkaline stability, such as in paper manufacturing and textile treatments.

Pyrogenic (Fumed) Silica Method:

Pyrogenic silica, or fumed silica, is produced through the high-temperature hydrolysis of silicon tetrachloride (SiCl4) in a hydrogen-oxygen flame.

Step-by-Step Process:

Hydrolysis: Silicon tetrachloride is vaporized and hydrolyzed at high temperatures, forming silica particles.

Collection: The resulting silica particles are collected and dispersed in water or other solvents to create a colloidal solution.

Stabilization: Stabilizers are added to maintain the colloidal dispersion and prevent particle agglomeration.

Applications: Fumed silica-based colloidal silica is used in high-performance applications requiring extremely fine particles, such as cosmetics, pharmaceuticals, and advanced materials.

Conclusion

The production of colloidal silica involves various methods, each designed to achieve specific characteristics and meet diverse industrial needs. From the sol-gel process to the use of alkaline silicon solutions, these methods ensure the creation of stable, high-quality silica sols with tailored properties. Understanding these production processes enables industries to optimize the use of colloidal silica in applications ranging from precision coatings and electronics to advanced ceramics and nanotechnology.