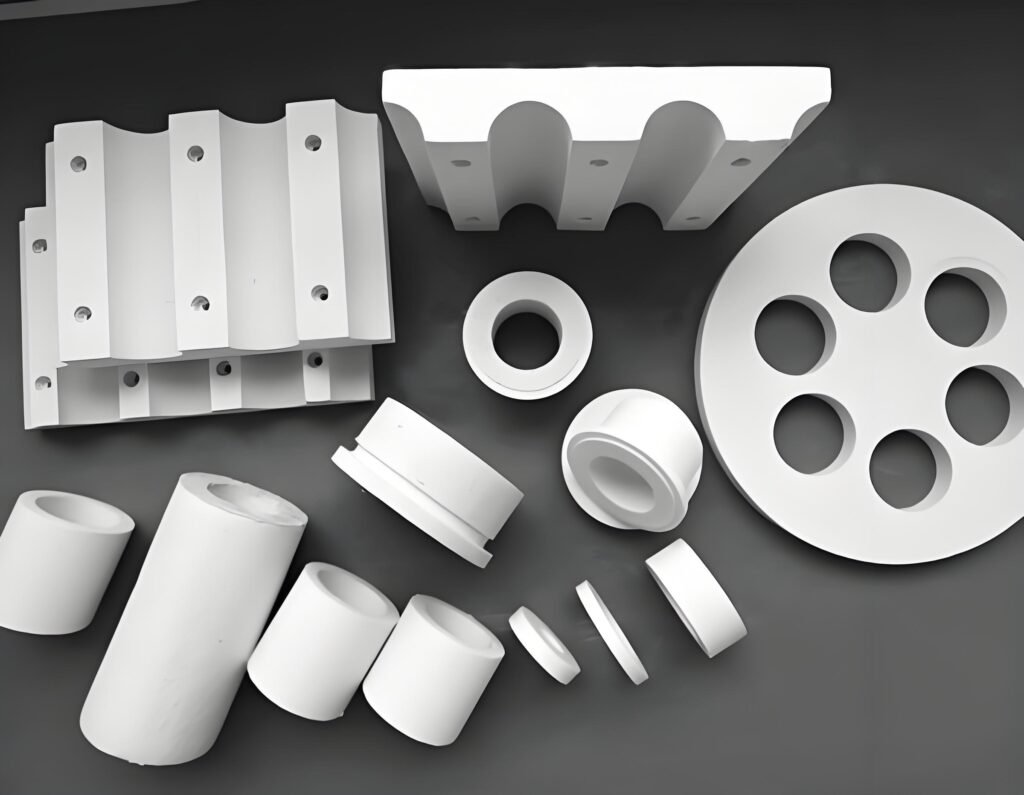

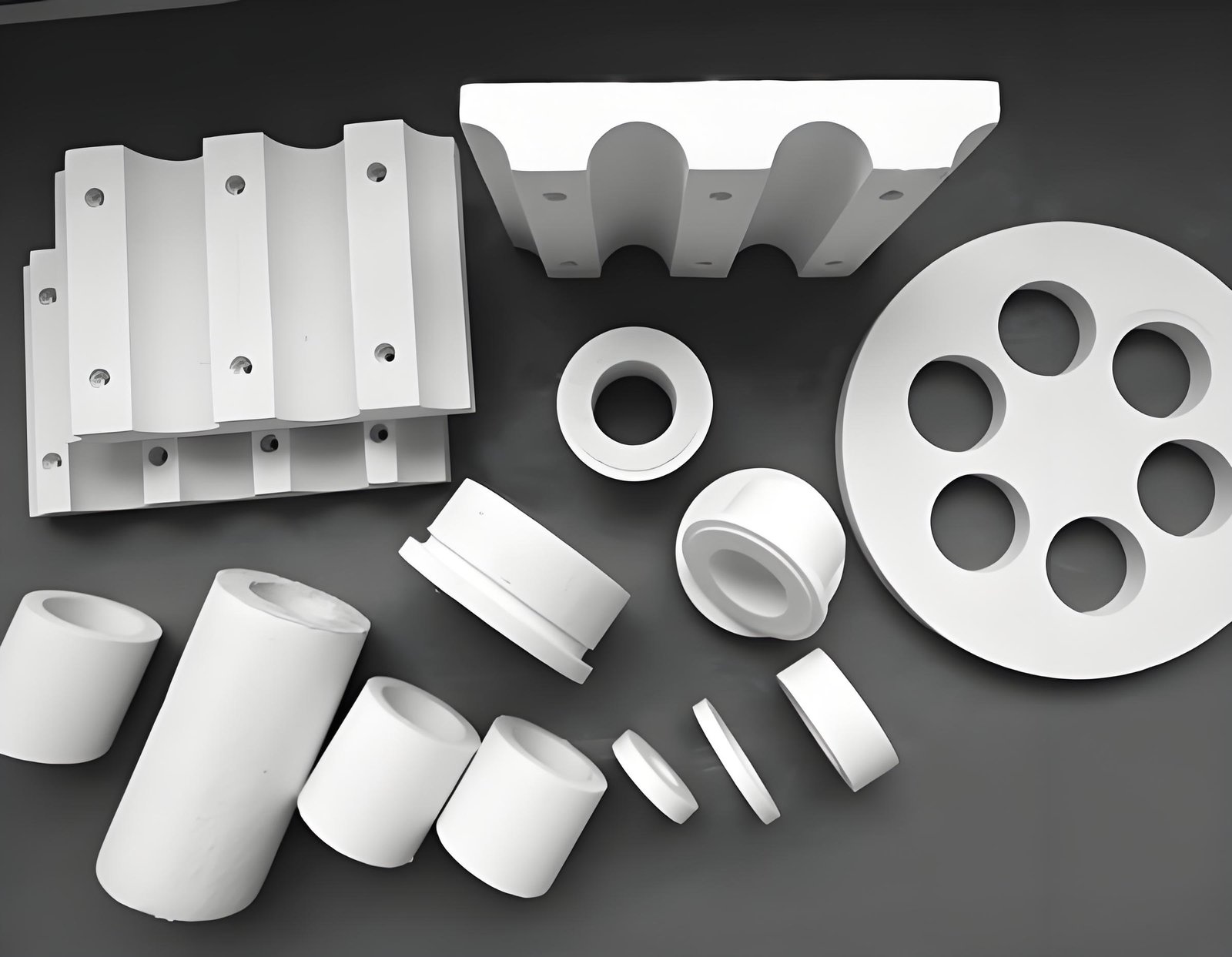

Ceramic fiber boards are indispensable in high-temperature applications, renowned for their exceptional thermal insulation, low thermal conductivity, and resistance to thermal shock. The integration of silica sol into these boards significantly enhances their performance. This post will delve into the properties of silica sol, its benefits for ceramic fiber boards, and the wide range of applications that benefit from this enhancement.

Understanding Silica Sol

What is Silica Sol?

Silica sol, a form of colloidal silica, consists of a stable dispersion of amorphous silica particles in a liquid, typically water. These nanoparticles, usually between 5 to 100 nanometers in diameter, remain uniformly suspended, providing unique properties such as high purity, stability, and excellent binding capabilities.

Key Benefits of Silica Sol in Ceramic Fiber Boards

1.Enhanced Structural Integrity

Binding Agent: Silica sol acts as a powerful binding agent, improving the structural cohesion of ceramic fiber boards. It penetrates the fiber matrix, reinforcing the connections between fibers, resulting in a more robust and stable board.

Longevity: This enhanced binding reduces the likelihood of deformation or cracking under high-temperature conditions, significantly extending the lifespan of the boards.

2.Superior Thermal Stability

High-Temperature Performance: The inclusion of silica sol enhances the thermal stability of ceramic fiber boards. These boards can withstand higher temperatures without degrading, making them suitable for extreme environments.

Consistent Insulation: Enhanced thermal stability ensures consistent insulation performance, critical for applications involving sustained high temperatures.

3.Reduced Shrinkage and Improved Dimensional Stability

Stabilization: Silica sol minimizes shrinkage by stabilizing the fiber structure, helping the boards retain their dimensions even after prolonged exposure to high temperatures.

Reliability: This dimensional stability ensures reliable performance in insulation applications, maintaining the effectiveness of the thermal barrier.

4.Increased Resistance to Thermal Shock

Thermal Cycling: Silica sol-treated boards exhibit excellent resistance to thermal shock, withstanding rapid temperature changes without cracking or breaking.

Versatility: This property is crucial for industries where thermal cycling is frequent, ensuring the boards remain intact and functional.

5.Enhanced Surface Hardness and Durability

Mechanical Resistance: The application of silica sol increases the surface hardness, making the boards more resistant to mechanical damage and abrasion.

Extended Service Life: Improved durability reduces maintenance needs and extends the service life of the boards in demanding environments.

6.Improved Insulation Properties

Thermal Insulation: Silica sol enhances the density and uniformity of the fiber matrix, improving the board’s resistance to heat flow.

Energy Efficiency: This results in better thermal insulation performance, contributing to energy efficiency in industrial applications.

Applications of Silica Sol-Treated Ceramic Fiber Boards

1.Industrial Furnaces and Kilns

Insulation: Used as insulation in furnaces and kilns, these boards benefit from enhanced thermal stability and resistance to thermal shock.

Efficiency: They improve the efficiency and lifespan of high-temperature equipment by providing consistent insulation.

2.Petrochemical Industry

Process Equipment: These boards insulate equipment and pipelines, protecting them from high temperatures and chemical exposure.

Safety: Enhanced durability and thermal stability contribute to the safety and efficiency of petrochemical processes.

3.Power Generation

Boilers and Heat Exchangers: In power plants, silica sol-treated boards are used in boilers and heat exchangers, ensuring reliable insulation under extreme conditions.

Operational Reliability: Their resistance to thermal cycling and high temperatures ensures consistent performance.

4.Aerospace and Defense

Thermal Protection: These boards provide thermal protection in aerospace and defense applications, such as in rocket engines and exhaust systems.

Performance: Enhanced properties ensure they meet the rigorous demands of these high-stress environments.

5.Glass and Ceramic Manufacturing

Kiln Insulation: Used in kilns and annealing ovens, these boards offer excellent insulation and durability.

Product Quality: They help maintain consistent temperatures, essential for high-quality glass and ceramic products.

6.Metallurgical Industry

Casting and Refining: The metallurgical industry uses these boards for insulating ladles, tundishes, and other high-temperature equipment.

Process Efficiency: Enhanced thermal properties improve the efficiency and safety of metallurgical processes.

Conclusion

Silica sol significantly enhances the performance of ceramic fiber boards, making them more robust, stable, and efficient for high-temperature applications. By improving structural integrity, thermal stability, resistance to thermal shock, and insulation properties, silica sol-treated ceramic fiber boards offer superior performance across various industries. These enhancements ensure that the boards meet the rigorous demands of industrial environments, providing reliable and long-lasting thermal insulation solutions.