In the vast landscape of materials science, few substances exhibit the versatility and utility of colloidal silica. With its remarkable properties and adaptability, colloidal silica finds applications across a diverse array of industries, driving innovation, efficiency, and sustainability. Let’s embark on a comprehensive journey to explore the profound impact of colloidal silica across 12 key sectors.

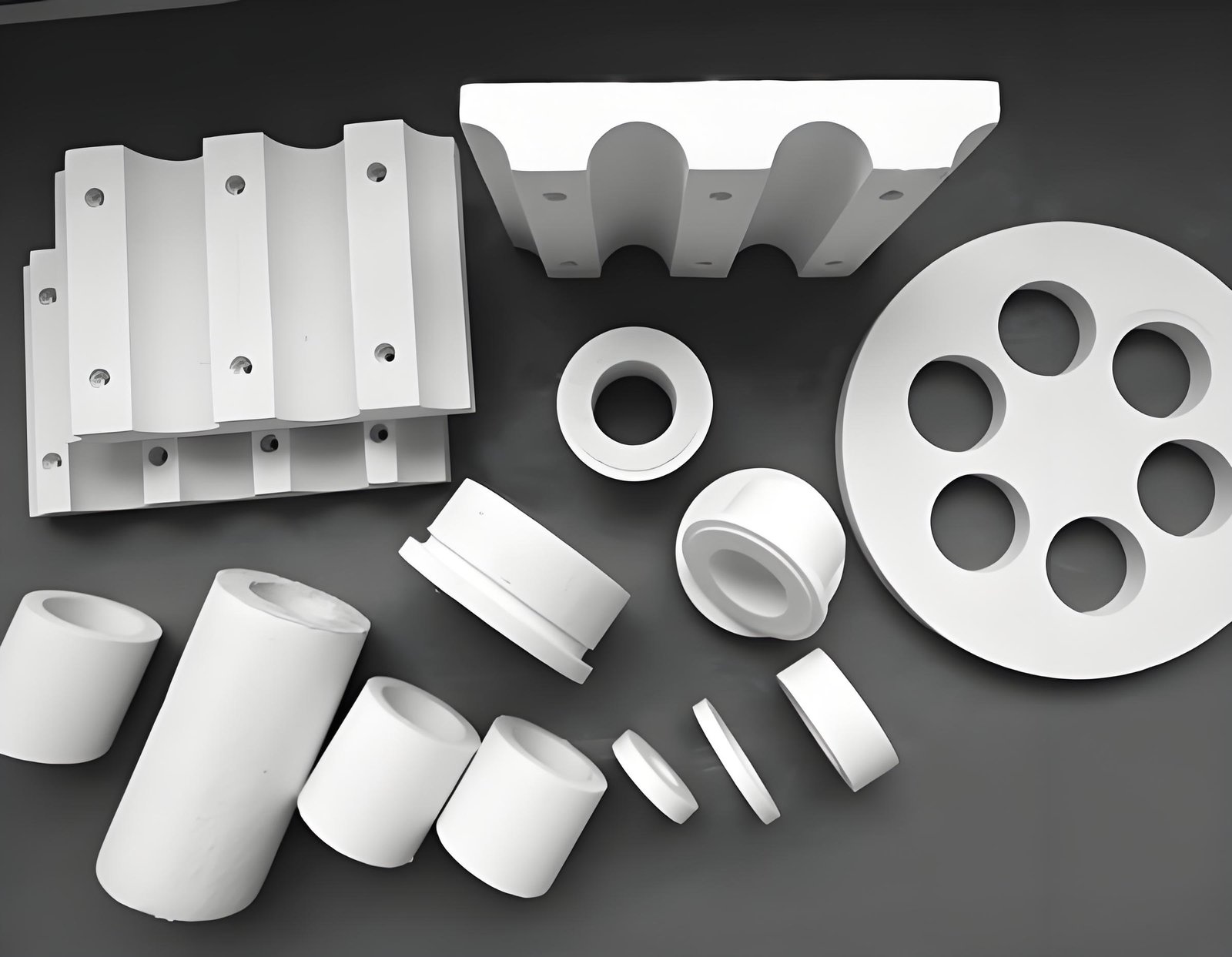

1. Investment Casting:

Colloidal silica’s role in investment casting is pivotal, serving as a binder in the creation of intricate metal components. By facilitating precise mold formation and delivering exceptional surface finish, colloidal silica enables the production of high-quality castings with intricate geometries and tight tolerances.

2. Paints and Coatings:

In the realm of paints and coatings, colloidal silica acts as a multifunctional additive, enhancing durability, adhesion, and weathering resistance. Its nano-sized particles contribute to improved rheology, film formation, and mechanical properties, resulting in coatings that exhibit superior performance and longevity.

3. Ceramics Polishing:

Colloidal silica’s abrasive nature makes it indispensable for ceramics polishing, where it achieves precise surface finishes and optical clarity. Whether in the production of semiconductor substrates or precision optical components, colloidal silica abrasives deliver unparalleled uniformity and consistency, ensuring the highest quality end products.

4. Refractory Materials:

As a binder in refractory materials, colloidal silica imparts strength and thermal stability to products used in high-temperature applications. Its ability to form strong bonds at elevated temperatures enhances the durability and performance of refractory linings in furnaces, kilns, and other industrial settings.

5. Electronics Polishing:

In the electronics industry, colloidal silica abrasives play a critical role in polishing semiconductor wafers and optical lenses. With their precise particle size distribution and controlled surface chemistry, colloidal silica slurries enable the production of microelectronics and precision optics with sub-micron accuracy and surface finish.

6. Textiles and Spinning:

Colloidal silica coatings enhance the lubricity and smoothness of textile fibers, reducing friction and static electricity during spinning and weaving processes. This results in yarns and fabrics with improved strength, uniformity, and softness, meeting the demands of diverse textile applications from apparel to industrial textiles.

7. Paper Industry:

In the papermaking process, colloidal silica serves as a retention aid and drainage aid, improving formation, strength, and dewatering efficiency. By optimizing fiber flocculation and enhancing sheet formation, colloidal silica additives enable the production of high-quality paper and board products with enhanced properties and reduced environmental impact.

8. Cosmetic:

Colloidal silica’s mattifying and oil-absorbing properties make it a valuable ingredient in cosmetic formulations. From skincare products to makeup formulations, colloidal silica helps to control shine, minimize pores, and create a smooth, matte finish, enhancing the performance and aesthetics of cosmetic products.

9. Water Treatment:

As a coagulant and flocculant aid, colloidal silica plays a crucial role in water treatment processes, facilitating the removal of suspended solids and impurities. Whether in municipal water treatment plants or industrial wastewater treatment facilities, colloidal silica aids in clarifying and purifying water, ensuring compliance with regulatory standards and safeguarding public health.

10. Catalyst Supports:

Colloidal silica’s high surface area and porous structure make it an ideal support material for catalysts used in a wide range of chemical processes. Whether in petrochemical refining, pharmaceutical synthesis, or environmental remediation, colloidal silica catalyst supports provide a stable and efficient platform for catalytic reactions, enabling the production of valuable chemicals and fuels with enhanced selectivity and yield.

11. Beverage Industry:

In the beverage industry, colloidal silica-based fining agents play a vital role in the clarification and stabilization of wines, beers, and fruit juices. By removing suspended particles and colloidal impurities, colloidal silica fining agents improve clarity, color, and flavor stability, enhancing the sensory attributes and shelf life of beverages.

12. Battery:

Colloidal silica coatings contribute to the performance and safety of lithium-ion batteries, particularly in electrode fabrication and electrolyte management. By enhancing electrode adhesion, preventing dendrite formation, and improving electrolyte wettability, colloidal silica coatings enable the production of high-performance batteries with enhanced energy density, cycle life, and safety.

Across these 12 industries, colloidal silica emerges as a versatile and indispensable material, driving innovation, efficiency, and sustainability. Its unique properties and wide-ranging applications underscore its significance as a foundational building block in materials science and engineering. By harnessing the full potential of colloidal silica and exploring novel applications, we pave the way for transformative advancements that benefit society, the environment, and the economy. Let us continue to unlock new avenues of possibility and push the boundaries of innovation with colloidal silica at the forefront.