Colloidal silica is a fascinating and highly versatile material widely utilized across numerous industries. Its unique properties and adaptability make it an essential component in many technological and manufacturing processes. To fully grasp the potential of colloidal silica, it is important to explore its different forms, each tailored for specific applications and performance characteristics.

Understanding Colloidal Silica

Colloidal silica is essentially a stable dispersion of ultra-fine, amorphous silica particles in a liquid, typically water. These particles are exceptionally small, usually ranging from 1 to 100 nanometers, allowing them to remain suspended in the liquid phase without settling out. The stability and uniformity of these particles give colloidal silica its unique and valuable properties.

Different Forms of Colloidal Silica

Acidic Colloidal Silica:

Description: This form of colloidal silica is stabilized in an acidic medium. The pH of acidic colloidal silica is typically below 7, often around 3-4.

Uses: Acidic colloidal silica is commonly used in applications where low pH is beneficial, such as in coatings, adhesives, and certain types of catalysts. Its stability in acidic conditions makes it ideal for use in environments where acidic resistance is crucial.

Alkaline Colloidal Silica:

Description: Alkaline colloidal silica is stabilized in a basic (alkaline) medium with a pH above 7, typically around 9-10.

Uses: This form is advantageous in applications requiring high pH stability, such as in paper production, textiles, and some types of refractory materials. The alkaline environment enhances the performance and stability of colloidal silica in these applications.

Neutral Colloidal Silica:

Description: Neutral colloidal silica has a pH close to 7, making it stable in neutral conditions.

Uses: It is often used in applications where neither acidic nor alkaline conditions are preferred. This form is versatile and can be used in a variety of industrial processes, including polishing and surface treatment applications.

High Purity Colloidal Silica:

Description: This type of colloidal silica undergoes rigorous purification processes to remove impurities, resulting in extremely high purity levels.

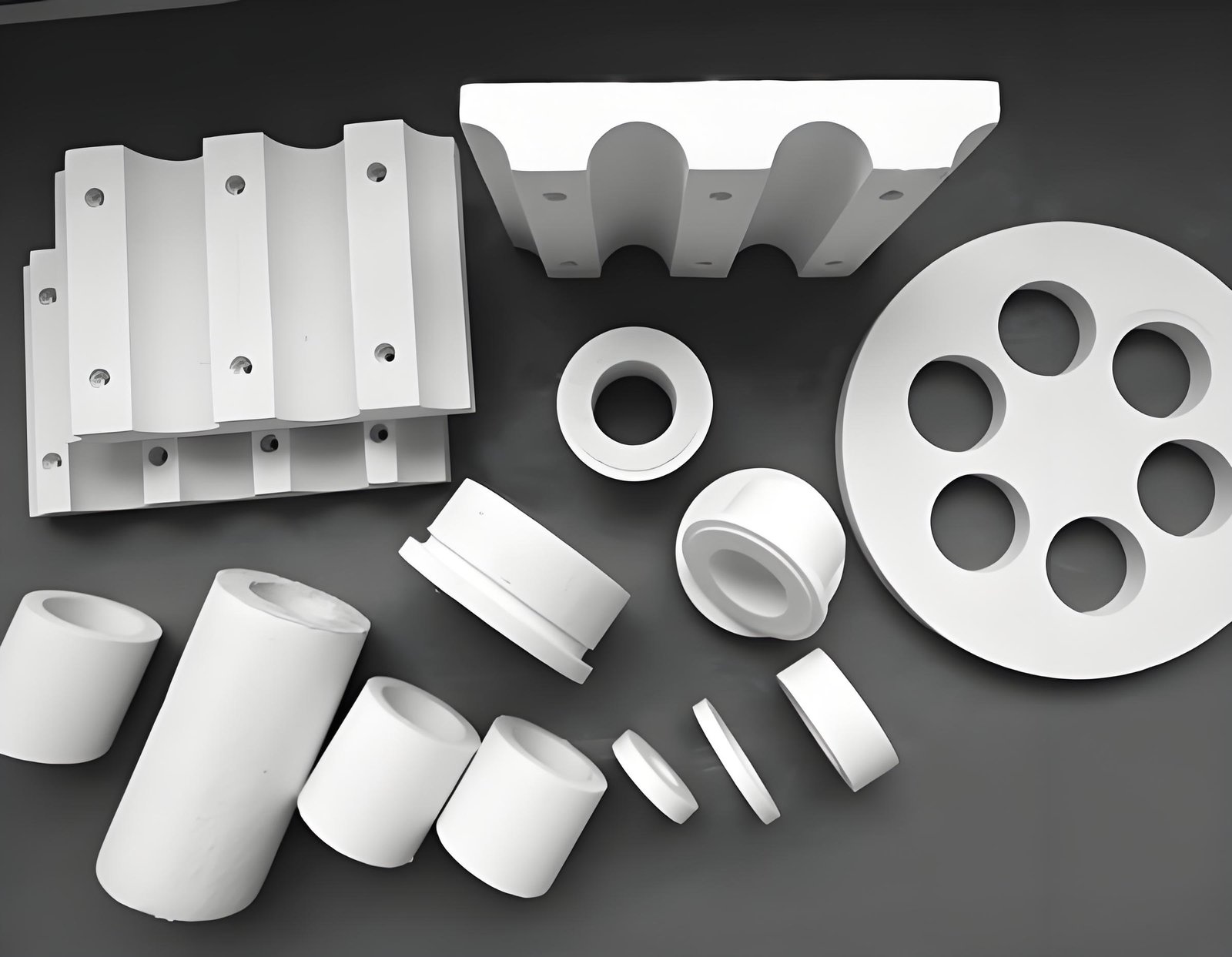

Uses: High purity colloidal silica is essential in industries where contaminants can significantly affect performance or safety, such as in semiconductor manufacturing, pharmaceuticals, and high-performance ceramics.

Modified Colloidal Silica:

Description: Modified colloidal silica involves surface modification of the silica particles to enhance specific properties such as hydrophobicity, oleophobicity, or functionalization with various chemical groups.

Uses: This form is tailored for specialized applications, including advanced coatings, biomedical applications, and as functional additives in composites and nanomaterials. The surface modifications can provide unique interactions with other materials, enhancing performance and functionality.

Fumed Silica-Based Colloidal Silica:

Description: Fumed silica is produced through the flame hydrolysis of silicon tetrachloride and then dispersed in water to create colloidal silica.

Uses: It is used in applications requiring extremely fine and high-surface-area particles, such as in cosmetics, pharmaceuticals, and as thickeners and rheology modifiers in various formulations.

Nano-Sized Colloidal Silica:

Description: This form emphasizes the ultra-small size of the silica particles, typically in the range of 1-20 nanometers.

Uses: Nano-sized colloidal silica is used in high-precision polishing, advanced material synthesis, and in areas requiring high reactivity and interaction at the nanoscale, such as in nanotechnology and biomedicine.

Hybrid Colloidal Silica:

Description: Hybrid colloidal silica combines silica particles with other nanoparticles or polymers to create multifunctional materials.

Uses: These hybrids are used in cutting-edge applications such as smart coatings, advanced composites, and multifunctional materials that require the combined properties of silica and other substances.

Colloidal silica exists in various forms, each engineered to meet specific industrial needs and performance requirements. From acidic and alkaline dispersions to high purity and modified versions, the versatility of colloidal silica makes it an indispensable material in modern technology and manufacturing. Understanding the different forms of colloidal silica allows industries to select the most appropriate type for their applications, optimizing performance, efficiency, and innovation across diverse fields.