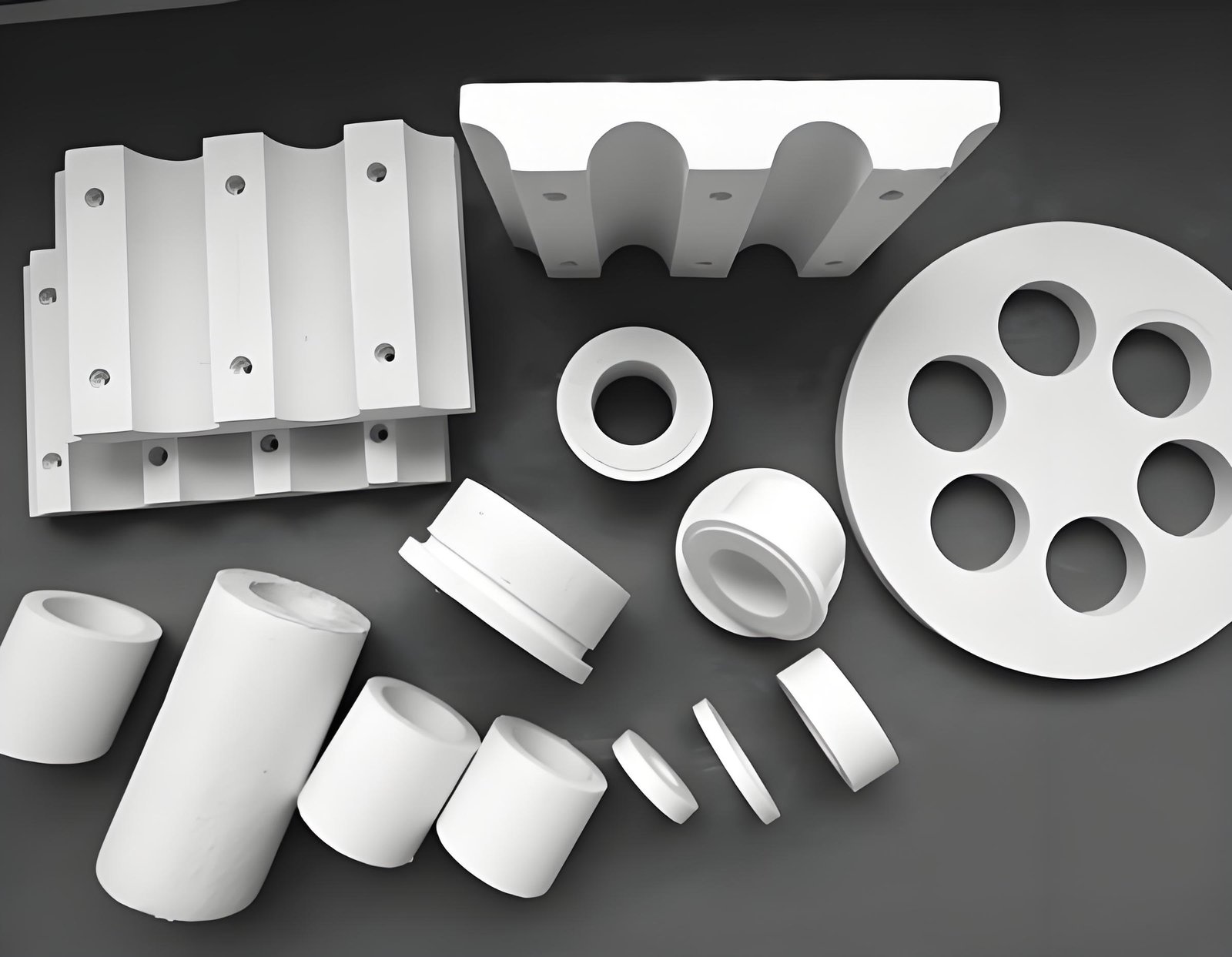

Investment casting, also known as precision casting or lost-wax casting, is a highly effective manufacturing process used to produce intricate metal parts with exceptional accuracy and surface finish. At the heart of this process is silica sol, a form of colloidal silica. Silica sol plays a crucial role in ensuring the quality and precision of investment castings. In this post, we will explore why silica sol is essential for high-quality investment casting and the properties that make it an indispensable component in this process.

1. Superior Binding Properties

Silica sol acts as an excellent binder in the investment casting process. When creating ceramic molds, silica sol helps bind fine refractory particles together, forming a robust and stable mold. This binding capability ensures that the mold retains its shape and structural integrity throughout the casting process, even under high temperatures and mechanical stresses. The strong bond formed by silica sol helps prevent mold deformation and cracking, leading to precise and high-quality castings.

2. High Purity and Consistency

Silica sol used in investment casting is known for its high purity and consistency. High-purity silica sol ensures that the ceramic molds are free from contaminants that could negatively impact the final metal castings. Consistency in the particle size and distribution of silica sol leads to uniform mold formation, reducing the likelihood of defects and variations in the final product. This level of purity and consistency is critical for producing components with tight tolerances and intricate details.

3. Optimal Particle Size and Distribution

The particle size and distribution of silica sol are optimized for the investment casting process. The fine, uniform particles of silica sol create a smooth and even mold surface, resulting in an excellent surface finish on the cast metal parts. This is particularly important for applications where surface quality is crucial, such as in aerospace, medical devices, and precision machinery. The optimal particle size also enhances the flow and penetration of the silica sol into the mold, ensuring complete and thorough coverage.

4. Stability and Durability

Silica sol provides stability and durability to the ceramic molds used in investment casting. The stable nature of silica sol ensures that the molds do not undergo significant changes during drying and firing. This stability is essential for maintaining the precise dimensions and features of the mold, which directly impacts the accuracy of the final castings. Additionally, the durability of silica sol-based molds allows them to withstand the thermal and mechanical stresses of the casting process without breaking or deteriorating.

Conduct On-Site Audits: If possible, visit the manufacturer’s facility to inspect their production processes and quality control measures firsthand.

Third-Party Testing: Engage independent laboratories to test the samples for key parameters such as particle size distribution, purity, and stability. This provides an unbiased assessment of the product quality.

Clear Specifications: Provide detailed specifications for the colloidal silica you require, including particle size, concentration, pH, and any other critical parameters. Clear communication ensures that the supplier understands your exact needs.

5. Enhanced Mold Refractoriness

The refractory nature of silica sol is another key factor that makes it indispensable in investment casting. Silica sol enhances the refractory properties of the ceramic molds, enabling them to withstand the high temperatures required for metal casting. This high-temperature resistance ensures that the molds remain intact and maintain their shape during the metal pouring and solidification stages, resulting in castings with excellent dimensional accuracy and surface integrity.

6. Improved Surface Finish

A significant advantage of using silica sol in investment casting is the superior surface finish it imparts to the final castings. The fine particles of silica sol create a smooth mold surface, which minimizes surface imperfections on the cast metal parts. This is particularly beneficial for producing components with complex geometries and fine details, as it reduces the need for additional finishing processes such as machining or polishing.

7. Eco-Friendly and Non-Toxic

Silica sol is an eco-friendly and non-toxic material, making it a safer choice for both the environment and workers involved in the investment casting process. Unlike some other binders and additives, silica sol does not release harmful fumes or byproducts during mold preparation or casting. This contributes to a safer and more sustainable manufacturing process, aligning with modern industry standards for environmental responsibility and worker safety.

Conclusion

Silica sol is an essential component in the investment casting process due to its superior binding properties, high purity, optimal particle size, stability, enhanced refractoriness, and ability to improve surface finish. These properties ensure that the ceramic molds used in investment casting are of the highest quality, leading to precise, durable, and high-quality metal castings. By leveraging the unique advantages of silica sol, manufacturers can achieve superior results in investment casting, producing components that meet the stringent demands of various high-performance applications.