In response to your needs, our R&D team continuously develop our broad portfolio of colloidal silica solutions

Under our main product brand Well ®, we offer several grades of fluid, low viscosity colloidal silica dispersions. The Well portfolio offers a wide range of particle size, surface areas, structure, concentration, pH, surface charge and surface modification which allows us to deliver the perfect colloidal silica product for your application. Just to give you an idea:

- By adding Well ® colloidal silica, you can improve anti-soiling properties in coatings such as silicate paints and elastomeric cool roof coatings.

- In catalyst manufacturing. Well ® provides advantages such as extended lifetime and higher productivity.

- In refractory materials,colloidal silica acts as a binder in refractory formulations, effectively bonding the refractory particles together.

Featured applications

where our colloidal silica is used

We offers a wide range of particle size, surface areas, structure, concentration, pH, surface charge and surface modification which allows us to deliver the perfect colloidal silica product for your application.

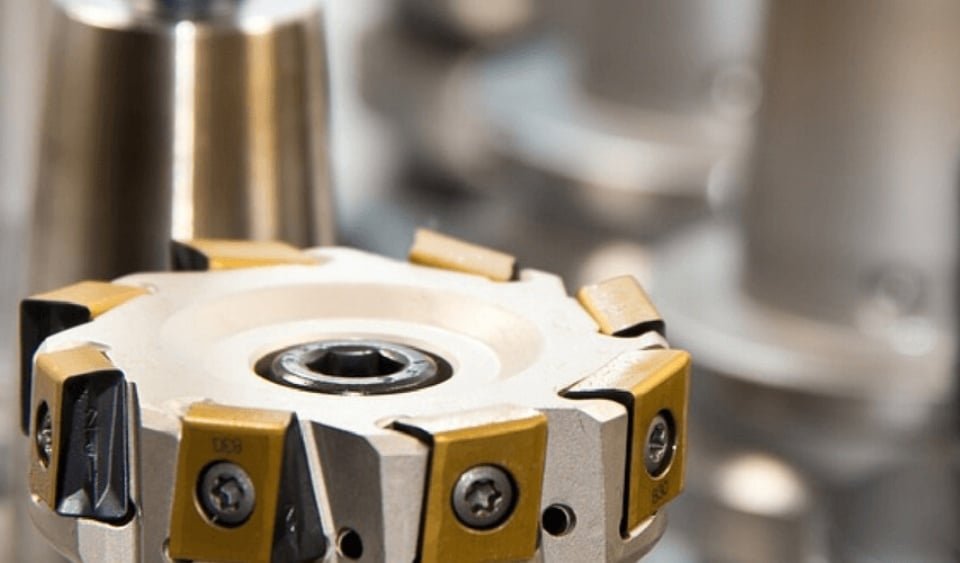

Investment Casting

Thanks to high temperature tolerance our colloidal silica products are used as a binder in foundry applications. Precision investment casting processes need to produce nearly flawless products. Colloidal silica offers several advantages. Besides increasing the capacity for greater mold intricacy, colloidal silica can withstand temperatures of 1500°C with little shrinkage and good resistance to thermal shock.

Recommend Products:

Paint and Coatings

Easy to use and safe to handle,our colloidal silica is the natural choice when making the switch from solventborne to waterborne coatings.It is a colloidal solution of inorganic polymer polymetasilicic acid with water as dispersion medium. With the evaporation of water, the colloidal molecules increase, and finally form – sio-o-sio-coating. Its water resistance and heat resistance are obviously better than organic coatings. Its coating is dense and hard, does not produce static electricity.

Recommend Products:

Ceramics Polishing

Colloidal silica plays a significant role in ceramics polishing by enhancing the surface properties and overall quality of ceramic materials.It is used as a polishing agent in ceramics to aid in minimizing defects and irregularities on the ceramic surface, such as cracks, pits, and unevenness.The polished ceramics exhibit enhanced clarity, brightness, and color vibrancy, making them visually attractive.

Recommend Products:

Refractory Materials

We Offer a broad range of colloidal silica for refractory material.Colloidal silica acts as a binder in refractory formulations, effectively bonding the refractory particles together. Providing excellent adhesion and cohesion,it enhances the strength, density, thermal insulation, and surface properties of refractories, contributing to their performance and longevity.

Recommend Products:

Electronics Polishing

Colloidal silica is widely used as an abrasive material in the various polishing stages of electronic components, such as integrated circuits (ICs), wafers, and other microelectronic devices. The ultra-fine particles of colloidal silica effectively polish surfaces, minimizing surface defects to ensure high-quality finishes on electronic components.

Recommend Products:

Textiles and Spinning

Colloidal silica can be applied to textile fibers and fabrics to improve their resistance to pilling, abrasion, and wear. It forms a protective coating on the fibers, reducing friction and preventing the formation of pills or fuzz. In addition,colloidal silica can improve the dye fixation and color fastness properties of textiles.

It acts as a binding agent, helping the dye molecules adhere to the fibers more effectively and enhancing the color retention and durability of the fabric.

Recommend Products:

Paper Industry

Colloidal silica has the characteristics of large specific surface area and strong reaction activity. It cab have a good chemical bonding effect with cationic surfactant and pulp fiber, play the role of retention and drainage aid, improve the retention rate of fine fibers and fillers, and the dehydration performance of the slurry.

It also apply to the surface of the paper to improve its surface properties, such as smoothness, gloss, and ink receptivity. This enhances the print quality and visual appeal of the final paper product.

Recommend Products:

Cosmetics

Colloidal silica plays a crucial role in cosmetics,particularly in makeup products like foundations, to create a matte appearance on the skin. The fine particles of silica help to absorb excess oil and reduce shine, giving the skin a smoother and more even texture. It also improves the texture of cosmetic formulations and helps in preventing the settling of heavy particles in liquid products, ensuring the even distribution of pigments and other components. This property is valuable in products such as lotions, creams, and liquid foundations.

Recommend Products:

Water Treatment

Colloidal silica acts as a coagulant aid and flocculant to remove suspended particles, pathogens, and contaminants, contributing to efficient surface water and wastewater treatment. It enhances clarification, filtration, and adsorption processes, while also serving as a catalyst support for advanced treatments. Additionally, colloidal silica helps control pH, mitigate disinfection byproducts, and prevent scaling and fouling in desalination and membrane filtration.

Recommend Products:

Catalyst Supports

Colloidal silica serves as an ideal catalyst support material to provide a reliable and efficient platform for catalysts, enabling enhanced catalytic activity, selectivity, and longevity in various chemical reactions and industrial processes. Notable applications include oil refining and petroleum processing, where colloidal silica is used as a “carrier” for the catalyst materials to enhance performance and product yield.

Recommend Products:

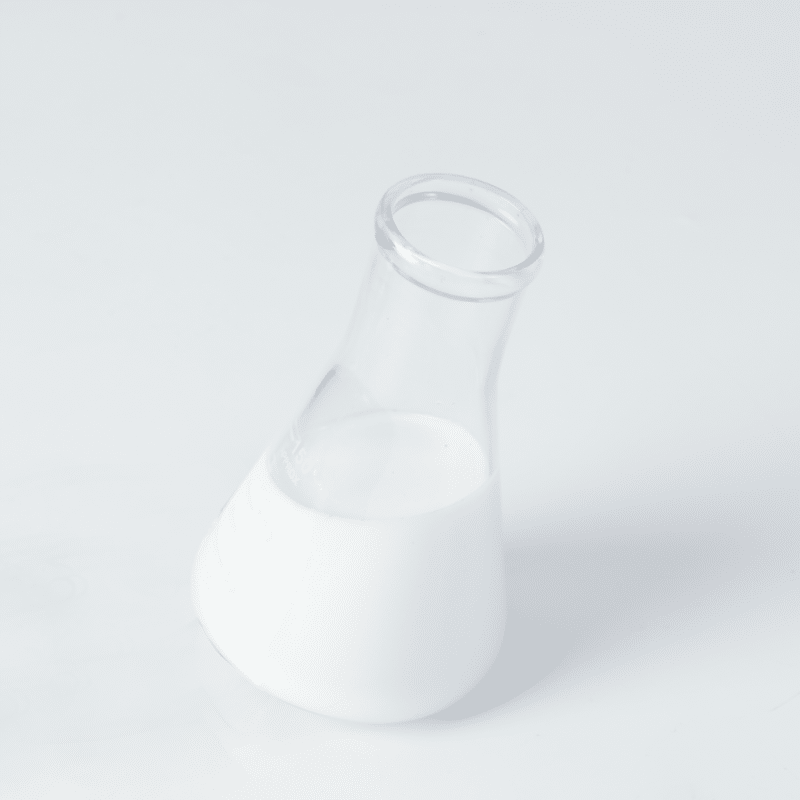

Beverage Industry

Charge neutralization is an important basis for the application of Colloidal silica as clarifier or flocculant in the beverage industry. In acidic fruit juice and wine, negatively charged silica sol reacts with positively charged gelatin to achieve the purpose of flocculation and clarification. One colloid can excite another colloid and make it easy to precipitate by electrolyte. Mixing colloidal solutions with different charges can make it co precipitate.

Recommend Products:

Battery

Colloidal silica enables the formation of a stable gel electrolyte in gel batteries, improving safety, vibration resistance, cycle life, thermal stability, and reducing maintenance needs. These features make gel batteries suitable for various applications, including renewable energy systems, telecommunications, emergency lighting, and portable devices.

Recommend Products:

Our Products

Contact Us

Get in touch

For more information about our products, please contact our experts. We look forward to hearing from you.